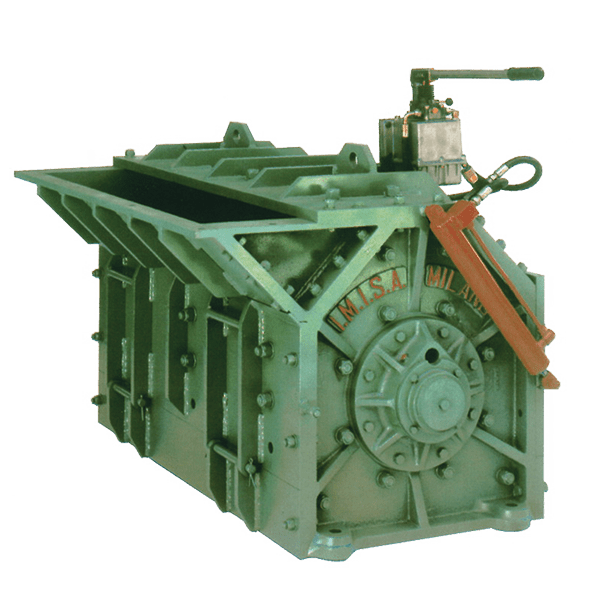

BODYFRAME

BODY SIDES

CRUSHING CHAMBER

BEARINGS SUPPORTS

REVOLVING ASSEMBLY

ROTOR

HAMMER PINS

SHAFT

HAMMERS

BEARINGS

SIZING GRATE

FEED OPENING

MODIFIED HAMMERMILLS FOR SPECIFIC UTILIZATONS:

For materials other than limestone, featuring distinctive characteristic (abrasive, hard, wet stones) or peculiar sizes, IMISA, on the ground of its long worldwide experience, is able to propose modified models specifically conceived tothe purpose, using hammers and armourings of the grinding chamber in special wear-resistant castings, as well as full stainless steel executions.

In this field IMISA is currently operating for processing glass, armoured glass, windshields, car and truk batteries, metal and non-metal junks, furnace slags, coal, sea-salt, rok-salt, phosphates, demolition waste, rofractory materials, pottery, porphiry, slate, basalt etc.

DOWNLOAD PDF

For more information or to request the product pdf write at this email address info@imisa1922.com