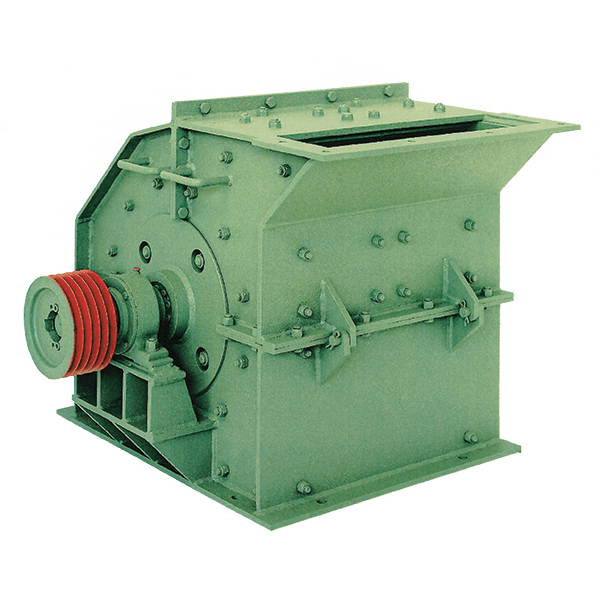

DUTY

COSTRUCTION

ROTOR

BEARING SUPPORTS

BEARINGS

GRINDING CHAMBER

HAMMERS

HAMMER PIVOTS

ROTOR SHAFT

GRATE

SPECIAL MILL TYPES

DOWNLOAD PDF

Per maggiori informazioni o per chiedere il pdf del prodotto scrivere all'indirizzo email info@imisa1922.com

Per maggiori informazioni o per chiedere il pdf del prodotto scrivere all'indirizzo email info@imisa1922.com